Spend less reagent

Miniaturize reactions so your most expensive components — like antibodies, enzymes, and cofactors — go dramatically farther.

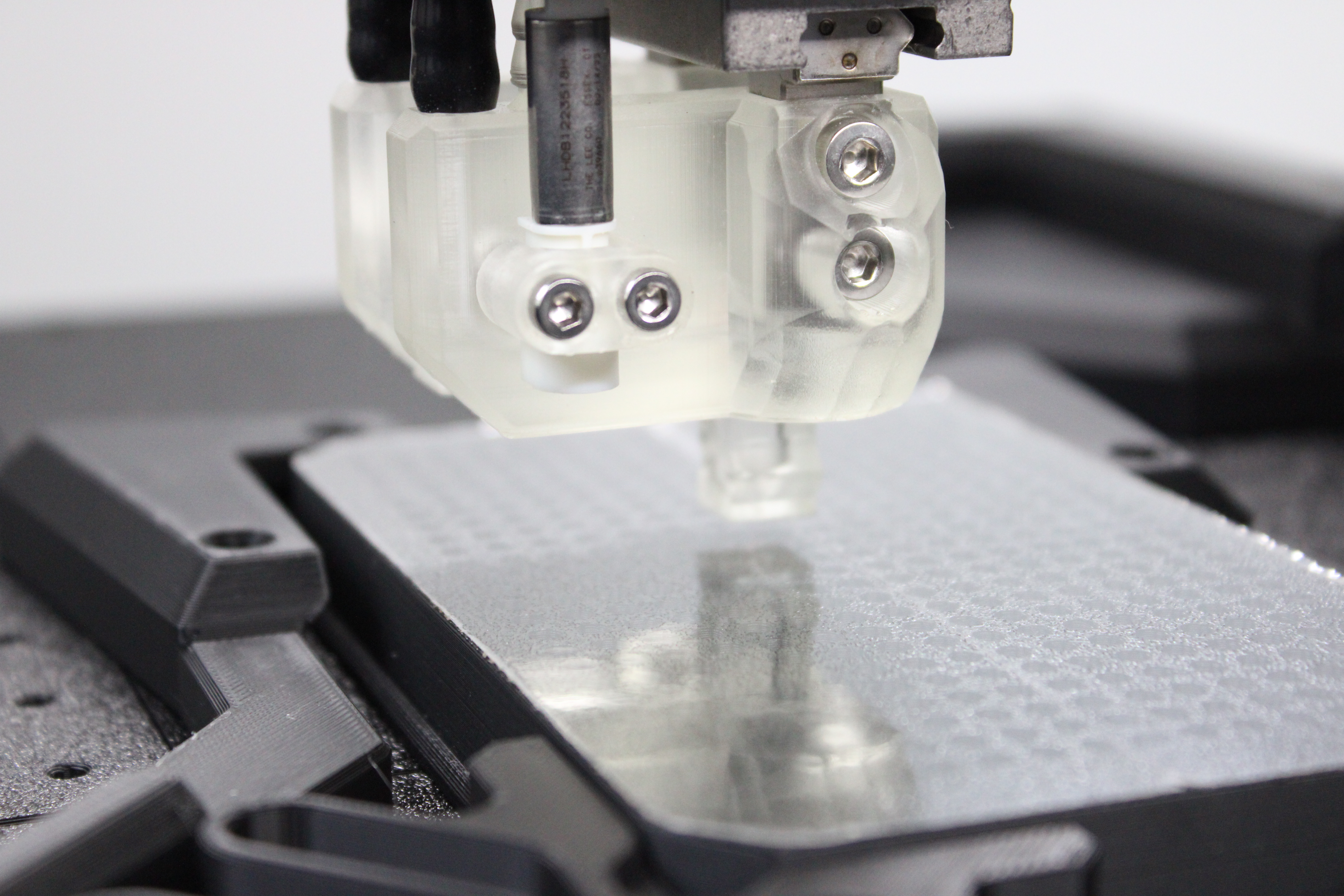

The LabCraft Plex prints 10–25 nL droplets at 20 Hz with reagent-specific calibration and onboard imaging verification — designed by scientists for scientists.

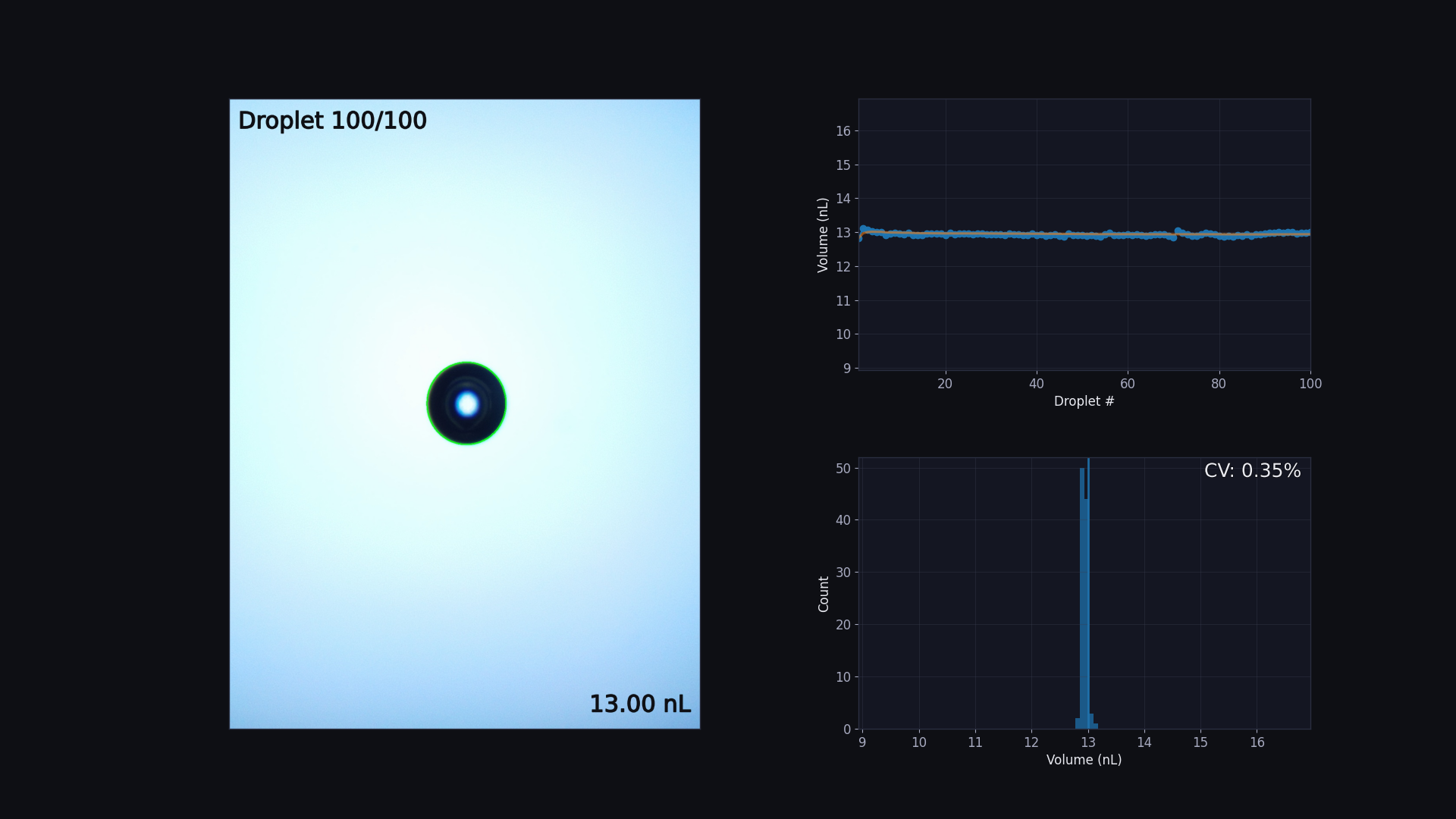

Precision depends on reagent properties and configuration; Plex verifies droplet formation and volume during calibration before printing a plate.

Biology happens at microscopic scales — your liquid handling should too. By reducing reaction volumes, you can conserve expensive reagents, test more conditions, and move faster without sacrificing accuracy.

Miniaturize reactions so your most expensive components — like antibodies, enzymes, and cofactors — go dramatically farther.

Explore larger experimental spaces: gradients and combinatorial designs become practical when assembly is fast and low-volume.

Droplets are imaged on-board to confirm formation and quantify volume, so you can run with confidence.

Droplet formation can vary with viscosity, surface tension, and nozzle geometry. Plex calibrates each reagent and verifies droplets with an on-board microscope so the volume you intend is the volume you dispense.

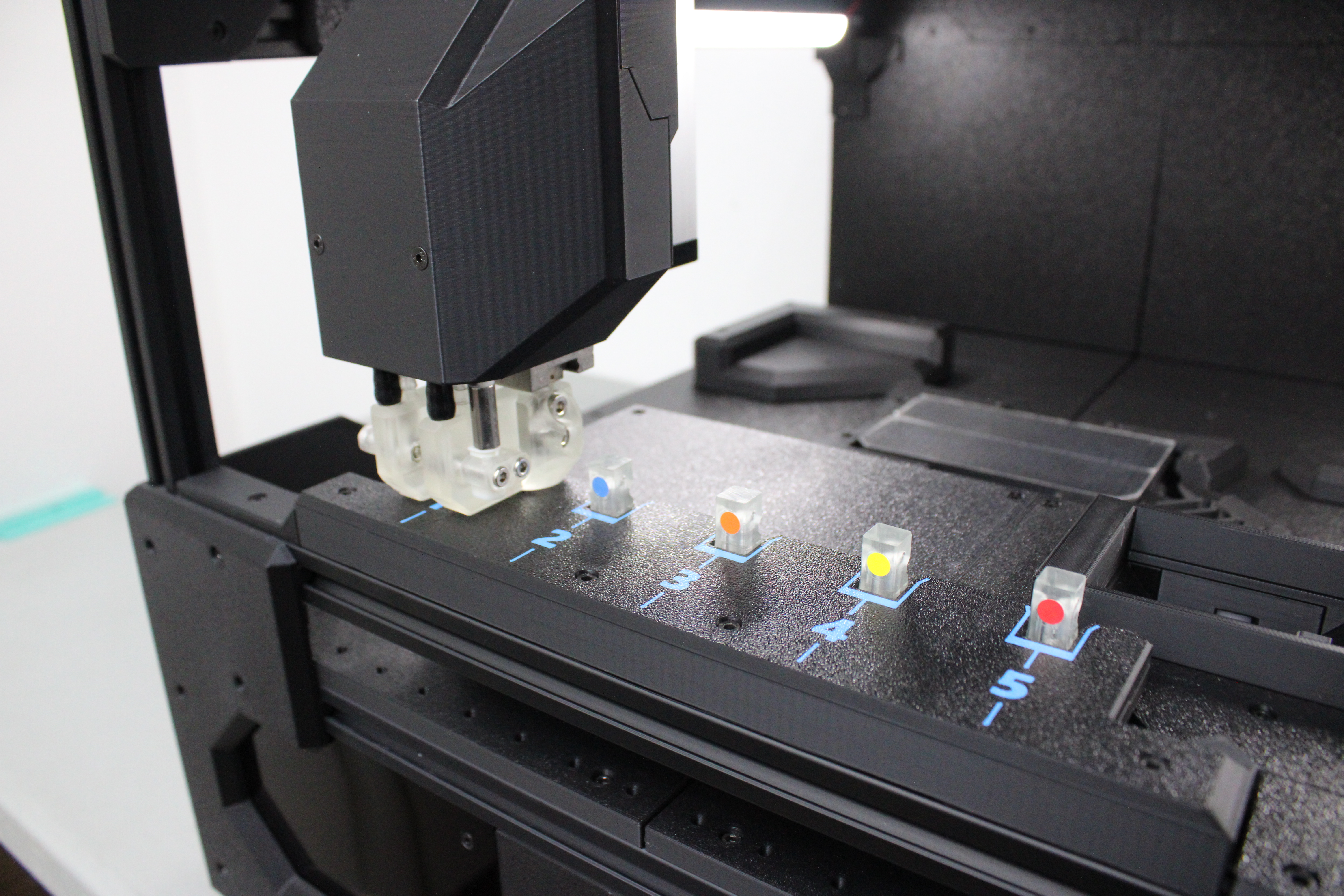

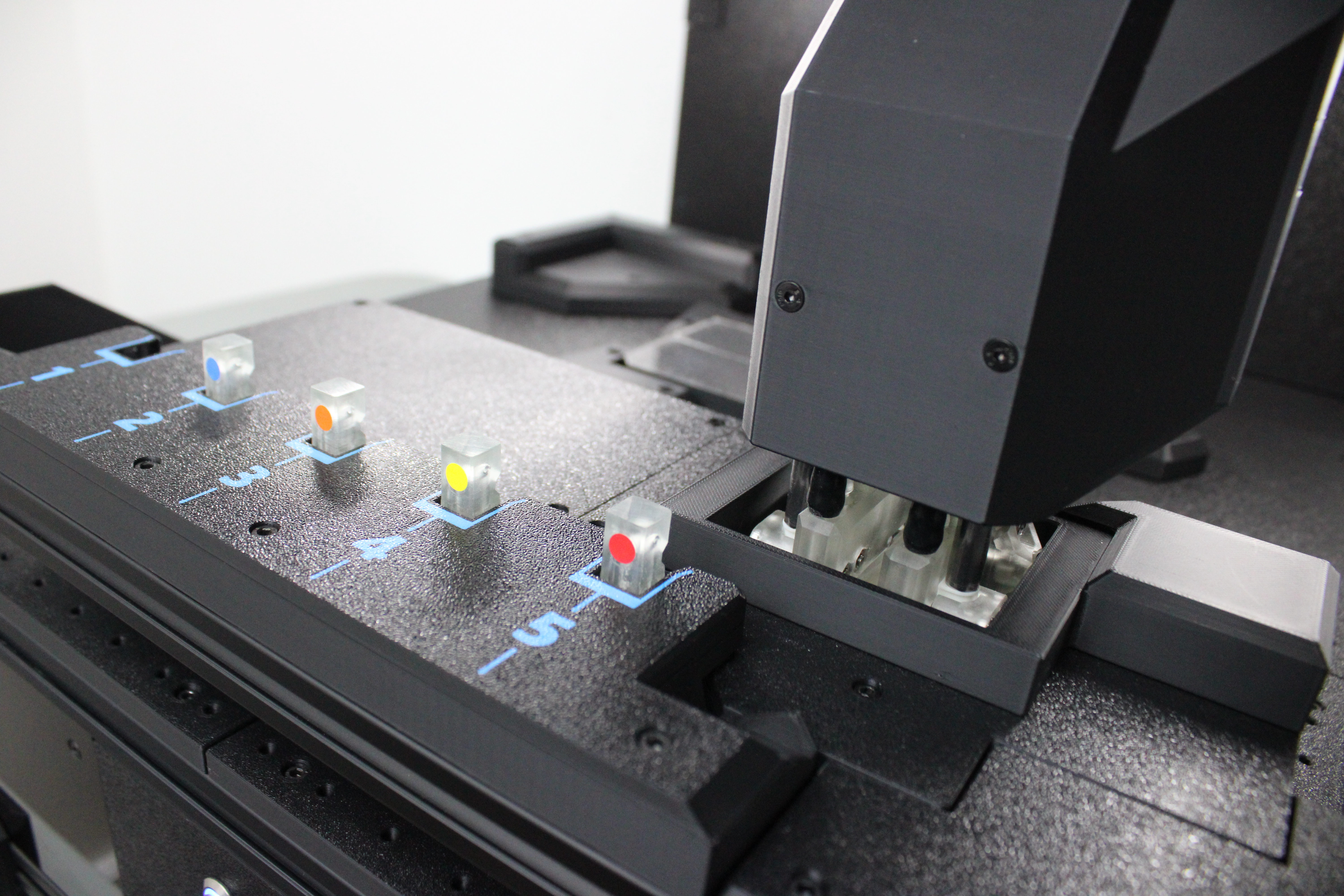

A practical workflow built for real lab work: load a head, calibrate, then print into your plate at speed. Swap heads mid-run to increase capacity for complex multi-reagent experiments.

Keep up to five heads loaded on the rack for fast switching, with the ability to swap heads during an experiment to reach up to fifteen total heads.

The system calibrates droplet formation for each reagent and images droplets to confirm consistent volumes before you print a full plate.

Dispense nanoliter droplets directly into well plates at 20 Hz for rapid experiment assembly — enabling large screens and dense condition coverage with minimal reagent usage.

Define the experiment you want — concentrations, combinations, replicates, and randomization — and the software computes stock solutions and droplet counts automatically. No spreadsheets. No scripting.

We’re onboarding a small number of partner labs. Share your assay and plate format — we’ll suggest a strong first evaluation experiment and outline expected reagent savings and condition coverage.